General Installation Information

- Home

- Hydraulic Sealing Elements

- General Installation Information

Before installation; we highly recommend to see section; General Installation Information of Technical Catalogue. Heating the seals before installation to +70°C hot oil will make the seal material more elastic and it will be easier to install the seal. It is very important not to create any condition to damage the material of the sealing element during this process.

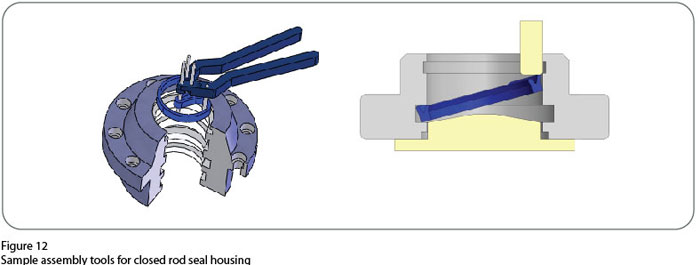

Hydraulic sealing elements can be installed to the open and closed grooves by hand. We recommend special assembly tools for the installation of the sealing elements in especially closed grooves. These assembly tools will speed up the installation and prevent the damaging of the sealing element. Different assembly tool samples can be seen in Figure 12.

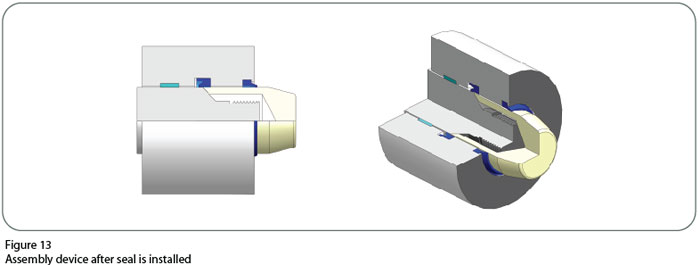

After the installation of the rod seals, in order not to have damage on the sealing elements while pushing the rod though the gland cap special assembly tool shown in Figure 13 should be used. All the assembly tools should not have any sharp edges and the surface roughness should be less than Rt ≤ 4µm.

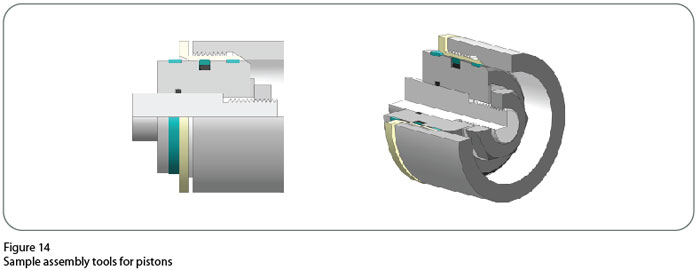

After the installation of the piston seals, in order not to have damage on the sealing elements while pushing the piston into the cylinder bore special assembly tool shown in Figure 14 should be used.

Installation of the compact seals into the rod piston is shown in Figure 15. Rubber sealing element can be easily installed with the aid of simple installation tool. The other parts of the compact seal can be installed easily by hand. See the following illustrations.

PTFE ROD SEALING ELEMENT INSTALLATION

All the assembly tools should be produced from soft material such as POM, PA, etc not have damage on the sealing elements during the installation process.

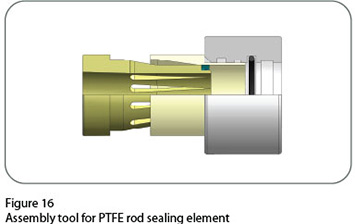

Sealing elements can be installed easily into open grooves. In order to prevent damage on the seals during the installation we recommend having open groove design. In closed grooves, the energizer ring is firstly installed in the housing. PTFE sealing element is placed on the front of the expanding mandrel. The conical sleeve is centered with the gland cap (Figure 16). Then expanding mandrel is moved inside the conical sleeve in order to install the PTFE sealing into the respective housing.