System Tolerances And Designs

- Home

- Hydraulic Sealing Elements

- System Tolerances And Designs

System tolerances are the important factors on the life span of the sealing elements. Inappropriate dimensions, tolerances and not centered hydraulic cylinders make the sealing elements wear out in short period of time and the system do not give the required performance.

All the dimensions and tolerances are indicated on the product pages of our catologue. Table 2 shows the general tolerances used in the hydraulic systems. The cylinder bore in hydraulic system is produced from ST 52 or better quality.

Sliding surfaces should have the mentioned operations (honed, grinded, etc) in order to obtain the required surface roughness values. Rods should be produced from steel (chrome plated, grinded and polished). Other cylinder parts should be from steel, steel casting, cast iron or special engineering plastics.

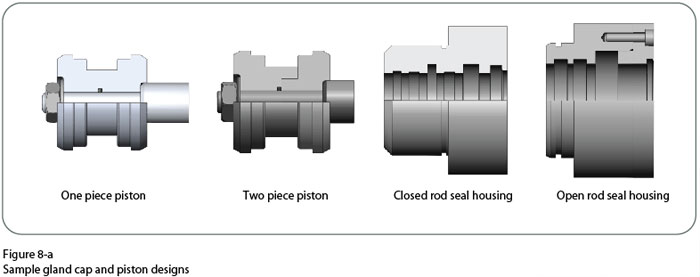

Below are some gland cap and piston designs in hydraulic cylinders depending on the sealing elements and applications;

|

NOMINAL DIMENSION |

HOLE TOLERANCES |

OD TOLERANCES |

||||||||||||

| > |

<= |

H8 |

H9 |

H10 |

H11 |

H12 |

e9 |

f7 |

f8 |

f9 |

h8 |

h9 |

h10 |

h11 |

|

3 |

+14 |

+25 |

+40 |

+60 |

+100 |

-14 |

-6 |

-6 |

-6 |

0 |

0 |

0 |

0 |

|

|

-0 |

-0 |

-0 |

-0 |

-0 |

-39 |

-16 |

-20 |

-31 |

-14 |

-25 |

-40 |

-60 |

||

| 3 |

6 |

+18 |

+30 |

+48 |

+75 |

+120 |

-20 |

-10 |

-10 |

-10 |

0 |

0 |

0 |

0 |

|

-0 |

-0 |

-0 |

-0 |

-0 |

-50 |

-2 |

-28 |

-40 |

-18 |

-30 |

-48 |

-75 |

||

| 6 |

10 |

+22 |

+36 |

+58 |

+90 |

+150 |

-25 |

-13 |

-13 |

-13 |

0 |

0 |

0 |

0 |

|

-0 |

-0 |

-0 |

-0 |

-0 |

-61 |

-28 |

-35 |

-49 |

-22 |

-36 |

-58 |

-90 |

||

| 10 |

18 |

+27 |

+43 |

+ 70 |

+110 |

+180 |

-32 |

-16 |

-16 |

-16 |

0 |

0 |

0 |

0 |

|

-0 |

-0 |

-0 |

-0 |

-0 |

-75 |

-34 |

-43 |

-59 |

-27 |

-43 |

-70 |

-110 |

||

| 18 |

30 |

+33 |

+52 |

+ 84 |

+130 |

+210 |

-40 |

-20 |

-20 |

-20 |

0 |

0 |

0 |

0 |

|

-0 |

-0 |

-0 |

-0 |

-0 |

-92 |

-41 |

-53 |

-72 |

-33 |

-52 |

-84 |

-130 |

||

| 30 |

50 |

+39 |

+62 |

+100 |

+160 |

+250 |

-50 |

-25 |

-25 |

-25 |

0 |

0 |

0 |

0 |

|

-0 |

-0 |

-0 |

-0 |

-0 |

-112 |

-50 |

-64 |

-87 |

-39 |

-62 |

-100 |

-160 |

||

| 50 |

80 |

+46 |

+74 |

+120 |

+190 |

+300 |

-60 |

-30 |

-30 |

-30 |

0 |

0 |

0 |

0 |

|

-0 |

-0 |

-0 |

-0 |

-0 |

-134 |

-60 |

-76 |

-104 |

-46 |

-74 |

-120 |

-190 |

||

| 80 |

120 |

+54 |

+87 |

+140 |

+220 |

+350 |

-72 |

-36 |

-36 |

-36 |

0 |

0 |

0 |

0 |

|

-0 |

-0 |

-0 |

-0 |

-0 |

-159 |

-71 |

-90 |

-123 |

-54 |

-87 |

-140 |

-220 |

||

| 120 |

180 |

+63 |

+100 |

+160 |

+250 |

+400 |

-85 |

-43 |

-43 |

-43 |

0 |

0 |

0 |

0 |

|

-0 |

-0 |

-0 |

-0 |

-0 |

-185 |

-83 |

-106 |

-143 |

-63 |

-100 |

-160 |

-250 |

||

| 180 |

250 |

+72 |

+115 |

+185 |

+290 |

+460 |

-100 |

-50 |

-50 |

-50 |

0 |

0 |

0 |

0 |

|

-0 |

-0 |

-0 |

-0 |

-0 |

-215 |

-96 |

-122 |

-165 |

-72 |

-115 |

-185 |

-290 |

||

| 250 |

315 |

+81 |

+130 |

+210 |

+320 |

+520 |

-110 |

-56 |

-56 |

-56 |

0 |

0 |

0 |

0 |

|

-0 |

-0 |

-0 |

-0 |

-0 |

-240 |

-108 |

-137 |

-185 |

-81 |

-130 |

-210 |

-320 |

||

| 315 |

400 |

+89 |

+140 |

+230 |

+360 |

+570 |

-125 |

-62 |

-62 |

-62 |

0 |

0 |

0 |

0 |

|

-0 |

-0 |

-0 |

-0 |

-0 |

-265 |

-119 |

-151 |

-202 |

-89 |

-140 |

-230 |

-360 |

||

| 400 |

500 |

+97 |

+155 |

+250 |

+400 |

+630 |

-135 |

-68 |

-68 |

-68 |

0 |

0 |

0 |

0 |

|

-0 |

-0 |

-0 |

-0 |

-0 |

-290 |

-131 |

-165 |

-223 |

-97 |

-155 |

-250 |

-400 |

||